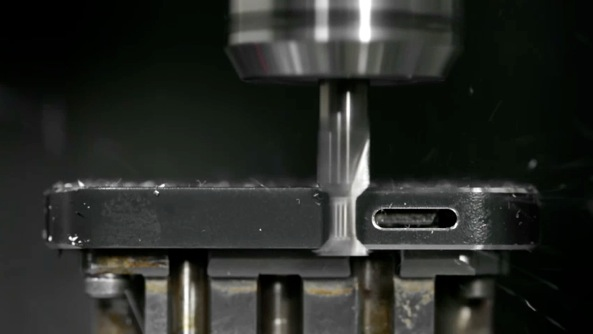

Precision Cleaning in Mobile Phone Manufacturing Industry

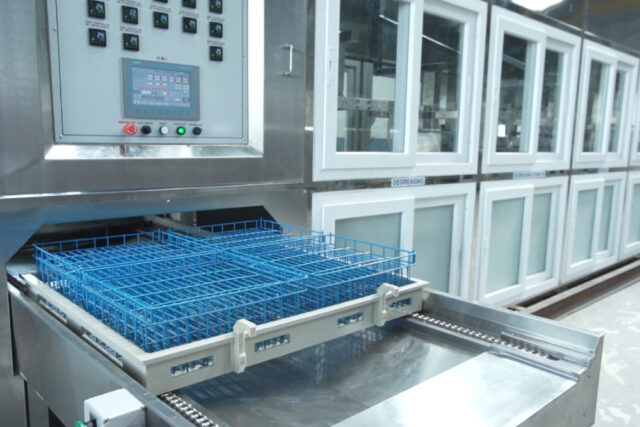

In the ever-evolving landscape of mobile phone manufacturing, the pursuit of perfection is a relentless journey. Each component, no matter how small, plays a crucial role in the creation of a flawless device. At the forefront of this quest for perfection is the application of multi-stage automated ultrasonic cleaning – a sophisticated process that is redefining precision cleaning in the mobile phone industry.

How can Ultrasonic Cleaning help?

Ultrasonic cleaning plays a crucial role in the cleaning of mobile phone parts manufacturing, offering several benefits that contribute to the overall efficiency and quality of the process. Here’s how ultrasonic cleaning helps in the cleaning of mobile phone parts manufacturing:

-

- Tailored Precision

The multi-stage approach allows manufacturers to customize the cleaning process for different components. Delicate parts receive the attention they deserve, ensuring optimal cleanliness without compromising functionality.

- Tailored Precision

-

- Efficient Removal of Contaminants

Ultrasonic cleaners use high-frequency sound waves to create microscopic bubbles in a cleaning solution. When these bubbles collapse, they generate intense shock waves that effectively remove dirt, dust, grease, and other contaminants from the surfaces of mobile phone parts.

- Efficient Removal of Contaminants

-

- Thorough Cleaning of Complex Structures

Mobile phones consist of intricate and delicate components, such as circuit boards, connectors, and small mechanical parts. Ultrasonic cleaning can reach into complex structures and tiny crevices that may be challenging to clean using traditional methods, ensuring a thorough cleaning process.

- Thorough Cleaning of Complex Structures

-

- Gentle on Electronic Components & Soft metals

Ultrasonic cleaning is a non-abrasive method, making it suitable for cleaning delicate electronic components found in mobile phones. It doesn’t involve harsh chemicals or mechanical scrubbing, reducing the risk of damage to sensitive parts like microprocessors, connectors, electronic circuits, and other soft metals like aluminum.

- Gentle on Electronic Components & Soft metals

-

- Time Efficiency

Ultrasonic cleaning is a relatively quick process. The cavitation action created by ultrasonic waves allows for rapid and simultaneous cleaning of multiple parts, contributing to increased efficiency and reduced cleaning time.

- Time Efficiency

-

- Consistent Cleaning Results

The ultrasonic cleaning process provides consistent and repeatable results. This ensures that mobile phone parts are consistently cleaned to a high standard, meeting quality control requirements in manufacturing processes.

- Consistent Cleaning Results

-

- High Volume Usability

Multi-stage ultrasonic systems, which are tailored and designed for the precision cleaning of mobile phone parts give phone manufacturers the option to make the machine run 24/7 usage and have full control over the production.

- High Volume Usability

-

- Process Control

Ultrasonic cleaning systems built for such an operation will give the manufacturer control over pre-cleaning inspection, ultrasonic power & frequency, cleaning solution composition, temperature control, agitation and immersion time, rinsing parameters, drying process, automated control systems, quality monitoring and inspection, record keeping and many more.

- Process Control

-

- Versatility

Ultrasonic cleaners can be used for a variety of mobile phone parts, including housings, and internal components. The versatility of ultrasonic cleaning equipment allows for the effective cleaning of different materials and surfaces.

- Versatility

Conclusion: Ultrasonic Cleaning and the Future of Mobile Parts Manufacturing

In conclusion, the importance of ultrasonic cleaning in mobile phone parts manufacturing is not just a technical necessity; it’s a pledge to deliver devices of unparalleled quality. It is a testament to the industry’s dedication to pushing boundaries, embracing innovation, and ensuring that each mobile phone that emerges from the production line is a masterpiece of cleanliness, reliability, and technological prowess. The echoes of ultrasonic cleaning resonate far beyond the assembly line, shaping a future where mobile devices are not just tools but manifestations of excellence in manufacturing.