Introduction: The Cleaning Revolution

In the world of precision cleaning, ultrasonic cleaners have emerged as game-changers, offering efficient and thorough cleaning for a variety of applications. Whether you’re a jeweler aiming for pristine gemstones, a healthcare professional seeking spotless medical instruments, or an industrial worker tasked with maintaining intricate machinery, choosing the right ultrasonic cleaner is paramount.

Understanding Ultrasonic Cleaning: How Does It Work?

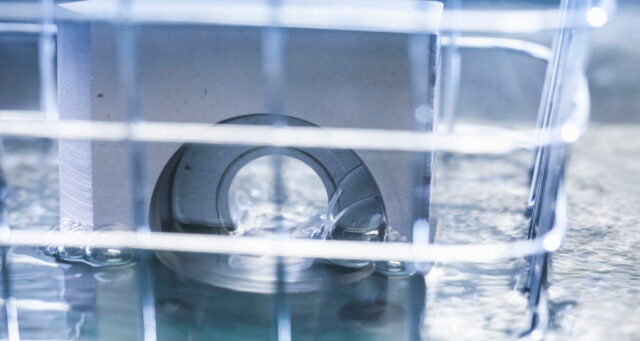

Before diving into the purchase guide, let’s briefly understand the science behind ultrasonic cleaning. Ultrasonic cleaners use high-frequency sound waves to create microscopic bubbles in a cleaning solution. These bubbles collapse rapidly, generating intense shock waves. This phenomenon, known as cavitation, produces small but powerful bursts of energy that effectively remove contaminants from surfaces.

Let’s get started with the apt guide to purchase your Ultrasonic Cleaner!

This guide will help you make an informed decision and find the best ultrasonic cleaner for your needs

-

- Application: Identify Your Cleaning Needs

The first step in choosing an ultrasonic cleaner is to identify your specific cleaning needs. Are you dealing with delicate jewelry, intricate medical instruments, automotive parts, or heavy-duty industrial equipment? The type and size of items you plan to clean will influence the specifications you should look for in a cleaner. Knowing your application ensures that the ultrasonic cleaner you choose is tailored to your requirements.

- Application: Identify Your Cleaning Needs

-

- Tank Capacity: Finding the Right Size

The size of the ultrasonic cleaner’s tank is a crucial factor. Consider the volume and quantity of items you’ll be cleaning. If you’re a hobbyist or a small-scale user, a compact unit with a smaller tank may suffice. However, for industrial applications, a larger tank is essential to accommodate bigger items and higher volumes. Striking the right balance in tank size ensures efficient cleaning without overcrowding.

- Tank Capacity: Finding the Right Size

-

- Frequency and Power: Balancing Act

Ultrasonic cleaners operate at different frequencies, typically measured in kilohertz (kHz). Higher frequencies (generally 40-68 kHz) are suitable for delicate items, while lower frequencies (20-40 kHz) provide more power for heavy-duty cleaning. Consider the nature of the items you’ll be cleaning and choose a frequency that aligns with your requirements. Additionally, ensure the unit has sufficient power to deliver effective cleaning. The balance between frequency and power is crucial for optimal performance.

- Frequency and Power: Balancing Act

-

- Tank Material and Construction: Built to Last

Durability is paramount when it comes to the tank material and construction. Stainless steel tanks are a popular choice for their corrosion resistance and longevity. Seamless or well-welded tanks prevent leakage, providing a secure environment for the cleaning process. Consider the build quality to ensure that your ultrasonic cleaner withstands the rigors of regular use.

- Tank Material and Construction: Built to Last

-

- Transducer Quality: The Heart of the Ultrasonic Cleaning System

The effectiveness of an ultrasonic cleaner is heavily dependent on the quality and design of its transducers. High-quality transducers ensure the generation of uniform and powerful ultrasonic waves throughout the cleaning tank. The number and arrangement of transducers also influence the overall performance of the ultrasonic cleaner.

- Transducer Quality: The Heart of the Ultrasonic Cleaning System

-

- Choosing B/W Manual & Auto Operation: The Crucial Choice

For anybody who is in the market looking for an ultrasonic cleaner, he/she needs to choose whether they want to purchase an ultrasonic system that requires human interference or a system that is fully automated. Usually, consumers with higher volume, those who have long production hours and where precision cleaning is a set standard, will go for auto-operated ultrasonic cleaning systems. However, for all other needs, consumers will go towards manually operated ultrasonic cleaning systems.

- Choosing B/W Manual & Auto Operation: The Crucial Choice

-

- Accessories & Additional Features: Enhancing Precision Cleaning

Depending upon cleaning requirements, the ultrasonic cleaning system would require a set of add-on accessories or features to complement and enhance the cleaning process. Examples include high-pressure jet washers, oil skimmers, the addition of rinsing and drying systems, filtration, and many more.

- Accessories & Additional Features: Enhancing Precision Cleaning

-

- Heating Function: Temperature Matters

Some ultrasonic cleaners come equipped with a heating function, allowing you to control the temperature of the cleaning solution. This feature is particularly useful for tasks that require elevated temperatures to enhance cleaning effectiveness. Adjustable temperature controls provide flexibility, ensuring that you can tailor the cleaning process to the specific needs of your items.

- Heating Function: Temperature Matters

-

- Timer and Digital Controls: Precision at Your Fingertips

Adjustable timers and digital controls are essential features that enhance the precision of your cleaning cycles. A user-friendly interface simplifies the operation of the ultrasonic cleaner, allowing you to set the desired cleaning time. These features not only improve efficiency but also contribute to a more user-friendly experience.

- Timer and Digital Controls: Precision at Your Fingertips

-

- Frequency Sweeping: Getting Rid of Dead Zones

It is designed to address the issue of dead zones and ensure a more uniform distribution of ultrasonic energy throughout the cleaning tank. Instead of operating at a fixed frequency, a frequency-sweeping ultrasonic cleaner constantly varies the frequency of the sound waves within a predetermined range.

- Frequency Sweeping: Getting Rid of Dead Zones

-

- Degas Function: Removal of entrapped gases

It is a specialized capability integrated into certain ultrasonic cleaners. It is specifically designed to remove entrapped gases from the cleaning solution. Entrapped gases can affect the efficiency of ultrasonic cleaning by creating a barrier between the cleaning solution and the items being cleaned.

- Degas Function: Removal of entrapped gases

-

- Safety Features and Ease of Use: 100% Safe

Safety should always be a priority. Look for ultrasonic cleaners with built-in safety features such as overheat protection and automatic shut-off. A drainage valve for fluid disposal adds convenience and ensures a hassle-free cleaning process. An easy-to-use ultrasonic cleaner with safety features provides peace of mind, especially during prolonged cleaning sessions.

- Safety Features and Ease of Use: 100% Safe

-

- Size & Portability: Because Size Matters

Beyond the tank size, consider the overall dimensions of the ultrasonic cleaner. A compact unit might be suitable for limited space environments, such as a laboratory or a small workshop. Larger units, often with increased tank capacity, are prevalent in industrial settings.

- Size & Portability: Because Size Matters

-

- Maintenance, Training & Support: No Support, No Business

Maintenance includes regular inspection, cleaning the tank, transducer care, replacing consumables, and calibration and adjustment. All of these are crucial pointers.

Know how to reach the manufacturer’s support team. This may involve a hotline, email, or an online support portal. Manufacturers often guide common issues, and troubleshooting steps, and can assist with more complex problems. All in all, the proper maintenance, training, and support for your ultrasonic cleaner are integral components of responsible ownership. Regular care and attention to the unit’s condition, combined with thorough user training and access to reliable support channels, ensure that your ultrasonic cleaner operates at its best over the long term.

- Maintenance, Training & Support: No Support, No Business

-

- Power Supply Compatibility: Being Specific

Ultrasonic cleaners are designed to operate within specific voltage ranges. Before making a purchase, it is imperative to check the unit’s voltage requirements. Common voltage specifications include 110V, 220V, or dual-voltage options that can accommodate different power supplies.

Understanding the type of power supply—whether single-phase or three-phase—is crucial. Single-phase power is common in residential settings, while industrial environments may utilize three-phase power. Ultrasonic cleaners are designed to work with specific power phases, and selecting the appropriate model ensures compatibility with the available power infrastructure. Note: Always refer to the manufacturer’s guidelines and specifications for power supply compatibility.

- Power Supply Compatibility: Being Specific

Conclusion: Your Path to Optimal Cleaning Efficiency

In conclusion, selecting the perfect ultrasonic cleaner involves a thoughtful consideration of your specific needs and the features offered by different models. From tank capacity to power density, each factor plays a vital role in determining the cleaning efficiency of the unit. By understanding the science behind ultrasonic cleaning and carefully evaluating these factors, you can make an informed decision that aligns with your requirements.

Embrace the power of precision and efficiency with Waveultra’s cutting-edge industrial ultrasonic cleaners – where innovation meets industry. Elevate your cleaning processes, secure your investments, and experience unparalleled performance. Trust in Waveultra for a future where cleanliness and productivity converge seamlessly in the industrial landscape.