Powering Precision: Innovating Manufacturing with Special Purpose Machines

In the realm of modern manufacturing, efficiency, and precision stand as cornerstones for success. Special Purpose Machines (SPMs) emerge as indispensable tools, tailored to specific tasks with laser-like focus. Let’s embark on a journey to unravel the essence of SPMs, elucidating their significance, functionalities, and how they stack up against conventional machines.

Understanding Special Purpose Machines

SPMs are bespoke machines meticulously crafted to perform designated tasks with unparalleled precision and efficiency. Unlike their conventional counterparts, which are versatile but lack specialization, SPMs are purpose-built for specific manufacturing processes. Their design is a testament to innovation, marrying engineering prowess with the intricacies of production demands.

Types & Applications

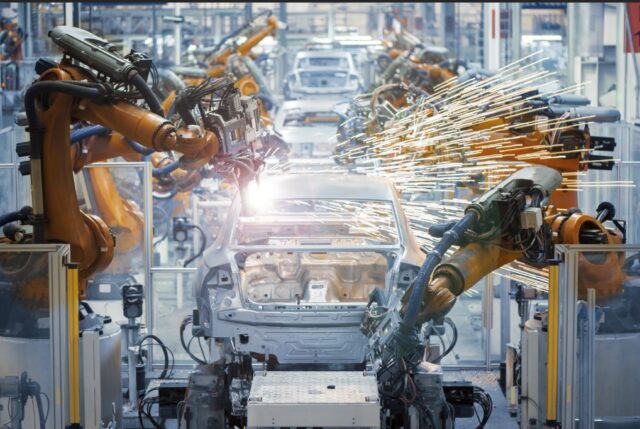

SPMs span a diverse spectrum of applications across various industries, from automotive and aerospace to electronics and consumer goods. They come in myriad forms, including assembly machines, packaging machines, welding machines, and machining centers. Each type is engineered to address specific manufacturing challenges, optimizing production throughput and ensuring consistent quality.

Key Characteristics of SPMs

-

- Custom Design

Each SPM is engineered for a specific need, often combining unique mechanical, electrical, and control systems. - Enhanced Efficiency

By eliminating unnecessary functionalities, SPMs optimize production for a particular task, often achieving higher output and faster cycle times. - Improved Quality

Dedicated design allows for tighter tolerances and reduced process variability, leading to consistent, high-quality products. - Automation

Many SPMs incorporate automation features, minimizing human intervention and streamlining production flow. - Reduced Labor Costs

Automating specific tasks through SPMs can reduce reliance on manual labor, leading to cost savings.

- Custom Design

Advantages of Special Purpose Machines

The adoption of SPMs heralds a paradigm shift in manufacturing efficiency, offering a plethora of advantages over conventional machines:

-

- Precision & Accuracy

SPMs excel in delivering precise and accurate results, thanks to their specialized design tailored to specific tasks. This precision translates into higher-quality products and reduced rework.

- Precision & Accuracy

-

- Enhanced Productivity

By streamlining manufacturing processes and eliminating unnecessary steps, SPMs boost productivity and throughput, leading to faster turnaround times and increased output.

- Enhanced Productivity

-

- Cost Efficiency

Despite initial investment costs, SPMs often prove more cost-effective in the long run due to lower operating costs, reduced labor requirements, and minimized material wastage.

- Cost Efficiency

-

- Flexibility and Adaptability

Contrary to the misconception of rigidity, SPMs can be designed with modular components and programmable features, offering flexibility to adapt to changing production needs.

- Flexibility and Adaptability

Examples of SPMs

- Assembly machines

Configured to perform complex assembly tasks with high precision and speed. - Testing machines

Designed to conduct specific tests on products, ensuring quality and functionality. - Material Handling machines

Customized for efficient loading, unloading, and manipulation of specific materials. - Machining Centers

Tailored for specialized machining operations, offering superior accuracy and speed.

Special Purpose Machines vs. Conventional Machines

Let’s delve into the intriguing comparison between Special Purpose Machines and their conventional counterparts:

| Feature | Special Purpose Machines (SPMs) | Conventional Machines |

| Purpose | Designed for a single, specific task | Designed for a variety of tasks with some adjustments |

| Production Volume | Ideal for high-volume, repetitive production | Suitable for low-volume, diverse production runs |

| Flexibility | Limited flexibility, may not adapt well to changes | Higher flexibility, can be used for different parts with adjustments |

| Cost | Higher initial investment due to custom design | Lower upfront cost, but may require additional tooling |

| Efficiency | Unmatched efficiency for the specific task | Lower efficiency when compared to dedicated SPMs |

| Precision | Ensures minimal tolerance variations and consistent high accuracy | Offers acceptable accuracy, may not be suitable for highly precise tasks |

| Labor Costs | Reduces labor costs through automation | May require more manual intervention |

| Safety | Often includes built-in safety features specific to the task | Rely on general safety measures, may require additional adaptations |

| Space Optimization | Compact design optimizes production line space | Larger size may require more floor space |

| Maintenance | Specialized maintenance requirements due to unique components | Easier to maintain due to standardized parts |

| Applications | Best suited for high-volume, precision-critical industries like automotive, aerospace, pharmaceuticals | Ideal for low-volume, diverse production needs across various industries |

Choosing the Right Machine

Selecting the optimal machine depends on various factors, including:

- Production volume

For high-volume, consistent production, SPMs excel. - Complexity of Task

If the task requires high precision and repeatability, SPMs are preferred. - Budget

If the task requires high precision and repeatability, SPMs are preferred. - Flexibility Needs

If adaptation to different tasks is crucial, conventional machines might be better.

The Future of Manufacturing

SPMs are not just niche solutions; they represent a growing trend in modern manufacturing. As production demands diversify and efficiency becomes paramount, the adoption of custom-tailored solutions like SPMs is expected to accelerate. Industry 4.0 technologies like automation and data analytics will further enhance the capabilities of SPMs, making them even more attractive for manufacturers seeking optimized production processes.

In conclusion, Special Purpose Machines emerge as the vanguards of manufacturing efficiency, revolutionizing production processes with their specialized capabilities. While conventional machines hold their ground in versatility, they pale in comparison to the precision, efficiency, and consistency offered by SPMs. As industries evolve and demand for customization grows, the role of SPMs will continue to expand, shaping the future of manufacturing with innovation and excellence.