Dual Frequency transducers in the field of ultrasonic cleaning

In the world of industrial cleaning, precision, and efficiency stand as crucial pillars. Whether it’s delicate medical instruments or intricate mechanical components, the need for thorough cleaning without causing any damage poses a significant challenge. However, innovative solutions have emerged to address this challenge, including the utilization of dual-frequency transducers in ultrasonic cleaning systems. These transducers are pivotal in augmenting the effectiveness of ultrasonic cleaning processes. Let’s explore the mechanics behind how dual-frequency transducers function within ultrasonic cleaning systems.

What are dual-frequency transducers?

High-pressure jet Cleaning utilizes pressurized water or cleaning solutions to dislodge and remove contaminants from surfaces.

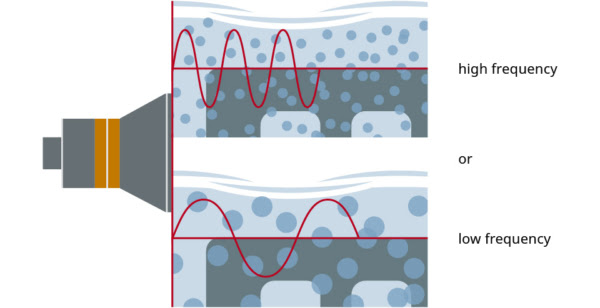

Before diving into the intricacies of their operation, let’s first understand what dual-frequency transducers are. In simple terms, a transducer is a device that converts one form of energy into another. In ultrasonic cleaning systems, transducers convert electrical energy into mechanical vibrations. As the name suggests, dual-frequency transducers can generate two distinct frequencies using the same transducer supported by a dual-frequency compatible ultrasonic frequency generator.

Operating Principles of Dual Frequency Transducers

Dual frequency transducers present a distinctive advantage in ultrasonic cleaning systems by offering flexibility in frequency selection. Operating within the kHz range, each frequency serves a distinct purpose:

-

- Low Frequency

The low-frequency component, typically ranging from 20 to 40 kHz, is primarily responsible for the bulk cleaning action. At this frequency, larger cavitation bubbles are formed, delivering powerful scrubbing action to remove stubborn contaminants from surfaces. This frequency is ideal for general cleaning applications where thorough removal of dirt and grime is required.

- Low Frequency

-

- High Frequency

In contrast, the high-frequency component operates in the range of 60 to 120 kHz. This higher frequency generates smaller cavitation bubbles, which are more effective in penetrating intricate crevices and tight spaces. The high-frequency vibrations provide a finer, more delicate cleaning action, making it suitable for sensitive materials or delicate components where precision cleaning is crucial.

- High Frequency

Advantages of dual frequency transducers

The option to choose two frequencies in the same system offers several advantages:

-

- Versatility

Dual frequency transducers allow operators to tailor the cleaning process to suit the specific requirements of different materials and applications. Whether it’s removing heavy grease from metal parts or gently cleaning delicate electronics, the ability to switch between frequencies enables greater versatility.

- Versatility

-

- Enhanced Cleaning Efficiency

By combining the advantages of both low and high frequencies, dual-frequency transducers deliver superior cleaning efficacy. The synergistic effect of the two frequencies ensures thorough cleaning across a wide range of surfaces and geometries.

- Enhanced Cleaning Efficiency

-

- Reduced Processing Time

With the option to utilize higher frequencies for finer cleaning followed by lower frequencies for bulk removal of contaminants, dual-frequency transducers can help reduce overall processing time without compromising on cleanliness.

- Reduced Processing Time

Conclusion

In conclusion, dual-frequency transducers represent a significant advancement in the field of ultrasonic cleaning technology. By harnessing the power of two distinct frequencies, these transducers offer enhanced versatility, efficiency, and precision in the cleaning process. As industries continue to demand higher standards of cleanliness and performance, the role of dual-frequency transducers in ultrasonic cleaning systems is poised to become even more prominent.

Feel free to connect with our team to understand how dual frequency based ultrasonic cleaning systems can help you with your desired requirement.