Selecting the Ideal Contract Manufacturer for Your Business

In the landscape of modern business, outsourcing manufacturing processes to contract manufacturers has become a strategic move for many companies. Whether you’re a startup aiming to scale efficiently or an established business seeking to streamline production, selecting the right contract manufacturer is a critical decision. This guide aims to navigate the key factors and considerations involved in choosing the perfect partner for your manufacturing needs.

Understanding Your Needs

Before diving into the selection process, it’s essential to have a clear understanding of your requirements. Outline your product specifications, production volume, quality standards, and budget constraints. This foundational step will serve as a roadmap for identifying the most suitable contract manufacturer.

Expertise and Specialization

One of the primary considerations when selecting a contract manufacturer is their expertise and specialization. Look for a partner with a proven track record in producing goods similar to yours. Assess their experience with relevant materials, processes, and industry standards.

Quality Standards and Certifications

Quality is non-negotiable in manufacturing. Ensure that your prospective contract manufacturer adheres to recognized quality standards such as ISO certifications. These certifications indicate a commitment to quality management systems, ensuring consistent and reliable production.

Capacity and Scalability

Consider the production capacity of the contract manufacturer concerning your needs. Are they equipped to handle your current volume requirements? Equally important is their scalability – can they accommodate your growth projections? A flexible partner who can adjust production levels as your business expands is invaluable.

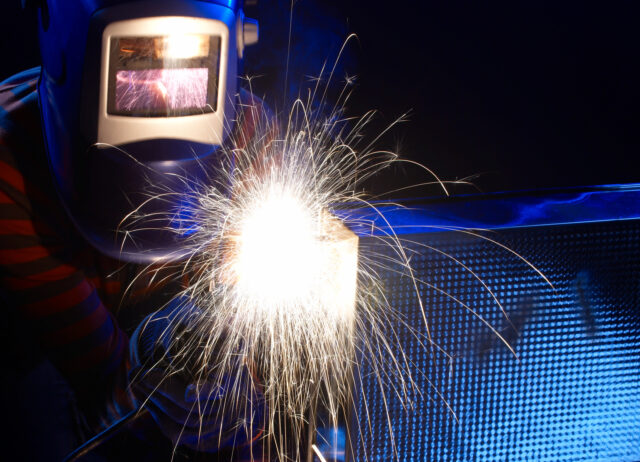

Technology and Equipment

Evaluate the technology and equipment utilized by the contract manufacturer. State-of-the-art machinery often translates to enhanced efficiency, precision, and cost-effectiveness. A manufacturer who invests in innovation demonstrates a commitment to delivering optimal results.

Location and Logistics

The geographical location of your contract manufacturer plays a significant role in logistics and supply chain management. Assess proximity to your distribution centres or markets to minimize shipping costs and lead times. Additionally, consider factors such as transportation infrastructure and potential geopolitical risks.

Communication and Transparency

Effective communication is fundamental to a successful partnership. Choose a contract manufacturer with a reputation for clear, open communication channels. They should provide regular updates on production status, and potential issues, and be responsive to your queries and concerns.

Financial Stability and Reputation

A reliable contract manufacturer should have a stable financial standing. Conduct due diligence on their financial health to ensure they can fulfil long-term commitments. Additionally, research their reputation within the industry, including client testimonials and case studies.

Environmental and Ethical Practices

In today’s socially conscious landscape, ethical considerations are paramount. Evaluate the contract manufacturer’s commitment to sustainable and ethical practices. This includes compliance with environmental regulations, responsible sourcing of materials, and fair labour practices.

Cost and Pricing Structure

While cost shouldn’t be the sole determining factor, it is undeniably significant. Request detailed quotes from potential contract manufacturers, including a breakdown of costs. Consider factors such as labour, materials, overheads, and any additional fees. Striking a balance between quality and cost-effectiveness is key.

Requesting and Reviewing Samples

Before finalizing your decision, request samples of previous work from the contract manufacturer. This allows you to assess the quality, finish, and attention to detail firsthand. Conduct rigorous testing and evaluation to ensure the manufacturer meets your standards.

Establishing a Strong Partnership

Once you’ve selected a contract manufacturer, focus on building a strong partnership. Clearly define roles, responsibilities, and expectations from both parties. Regularly assess performance metrics and address any issues promptly to maintain a productive relationship.

Choosing the right contract manufacturer for your business is a pivotal step towards success in the competitive market landscape. By understanding your needs, and evaluating key factors such as expertise, quality standards, capacity, and communication, you can make an informed decision. A strategic partnership with the ideal contract manufacturer can unlock efficiency, quality, and growth opportunities for your business.

In the ever-evolving world of manufacturing, the right partner can propel your business to new heights of success. Conduct thorough research, ask pertinent questions, and prioritize compatibility and shared goals. With careful consideration and due diligence, you’ll find the perfect contract manufacturer to bring your vision to life.

Feel free to connect with our team to know more about contract manufacturing