Quality Systems Designed for Aerospace Standards

Engineering with Core Values

Quality & Surface Engineering Capabilities .

Our vision and values guide every decision, shaping how we engineer reliable, innovative solutions for our customers.

Dimensional Inspection & Verification

CMM and precision measurement systems for accurate dimensional validation.

Process Documentation & Traceability

Inspection records and validation reports to support aerospace compliance.

Aerospace-Aligned Quality Practices

Quality systems aligned with AS9100D requirements (certification in progress).

Surface Preparation & Cleaning Integration

In-house ultrasonic cleaning and surface treatment processes for controlled surface quality.

Industries We

Serve

.

Aerospace & Defence

Precision-machined components requiring verified quality and surface control.

Medical Devices & Healthcare

Surgical instruments and medical components used in hospitals, requiring controlled and repeatable cleanliness levels.

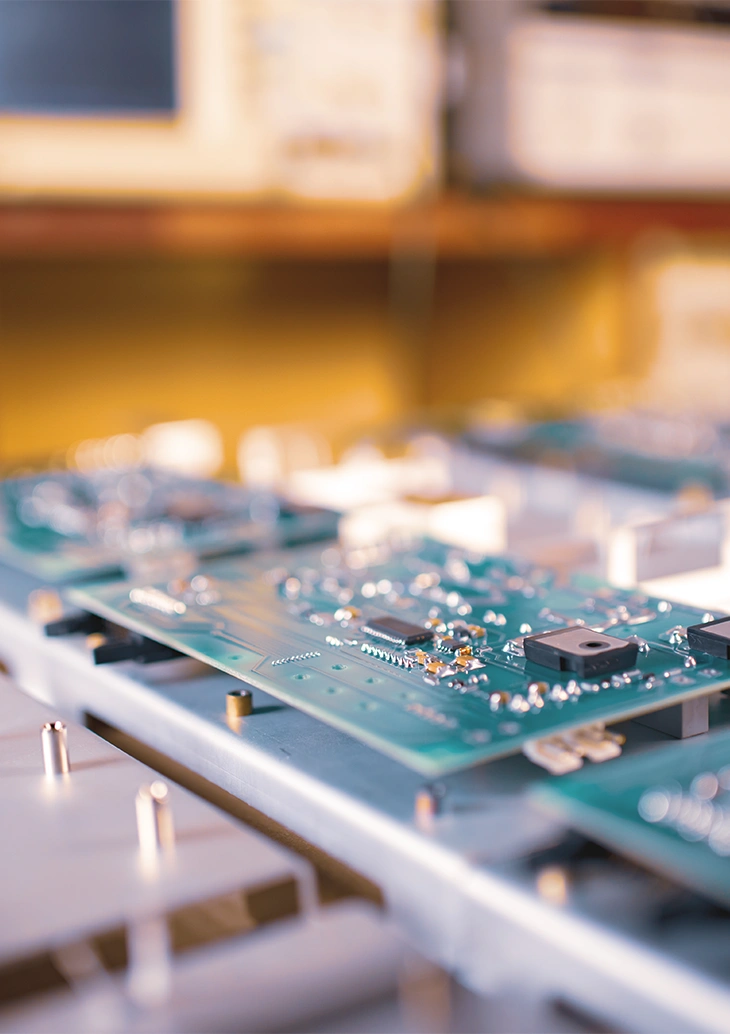

Electronics & Semiconductor Manufacturing

Components require strict cleanliness and contamination-free surfaces.

Precision Automotive Systems

High-value automotive parts where surface integrity and dimensional accuracy are critical.

The Role of Quality & Surface Engineering in Aerospace

01.

02.

Reduces variability through integrated processes

03.

Supports compliance with aerospace standards

04.

Minimizes contamination and handling risks

05.

Improves overall manufacturing reliability

Discuss Your Requirement

Reach out to explore feasibility, process approach, and precision standards.