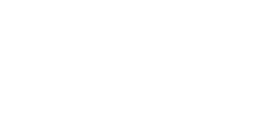

Leaders in Precision Manufacturing and Ultrasonic Cleaning

Years of Experience

Projects Delivered

Total Employee

World Wide Clients

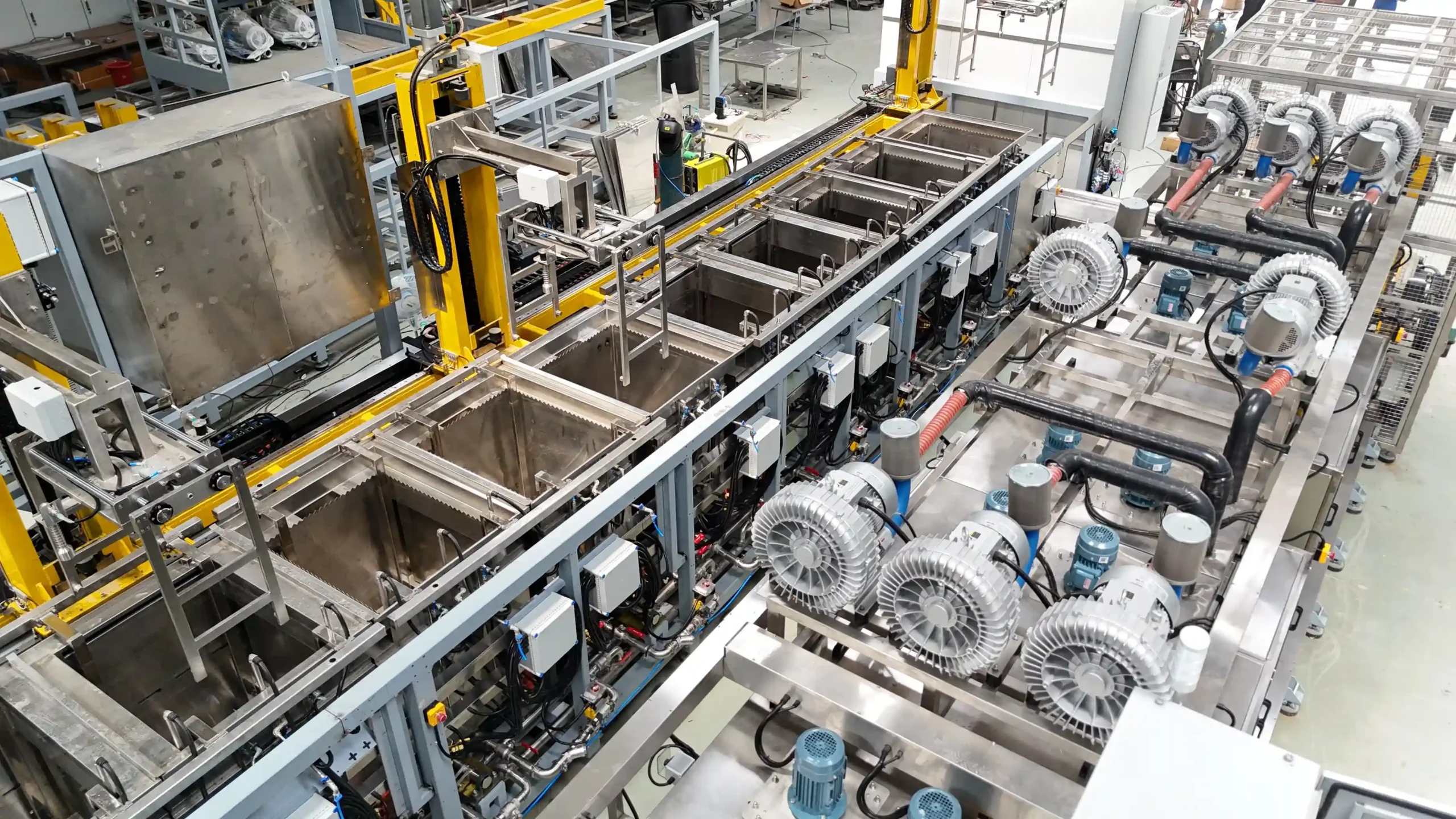

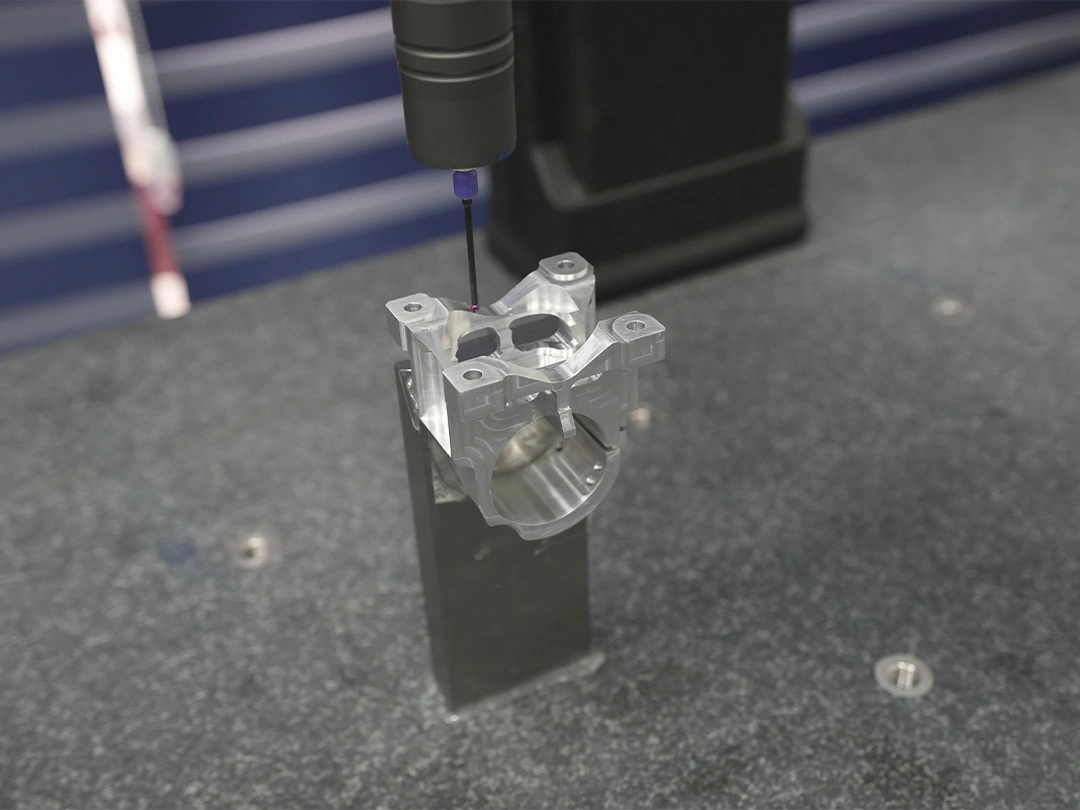

Aerospace.

Precision manufacturing built for accuracy, consistency, and compliance.

Automation.

Process-driven automation systems designed for control and efficiency.

Industries We

Serve

.

We serve quality-driven industries with precision engineering and automation solutions designed to meet strict performance, reliability, and compliance requirements.

Semiconductor

Waveultra delivers ultrasonic cleaning and automation systems designed for contamination-sensitive components, supporting strict cleanliness standards required in semiconductor and mobile manufacturing environments.

Aerospace

We support aerospace programs with precision machining, controlled surface preparation, and inspection-driven manufacturing, ensuring compliance with stringent aerospace and defence requirements.

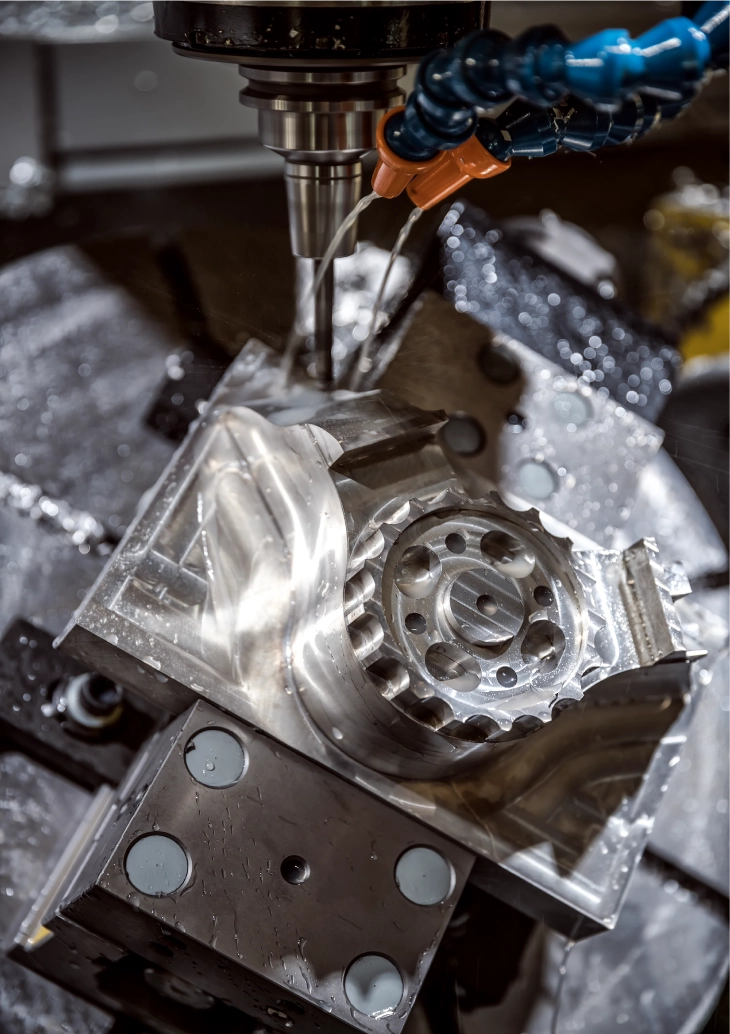

Machining Works

Our systems support machining environments by ensuring effective pre- and post-machining cleaning, surface readiness, and process integration for high-value precision components.

Automotive & EV

Built to meet the industry’s strictest specs, Waveultra delivers flight-critical components with precision, speed, and audit-ready quality. From prototypes to full-scale production, we reduce cost, boost performance, and help you stay mission-ready.

Healthcare & Scientific

We design precision cleaning and automation solutions for healthcare, laboratories, and scientific facilities where accuracy, repeatability, and contamination control are essential.

Watch & Jewellery

Waveultra’s ultrasonic cleaning systems are widely used for fine components in watchmaking and jewellery, ensuring gentle yet effective cleaning without surface damage.

Infrastructure .

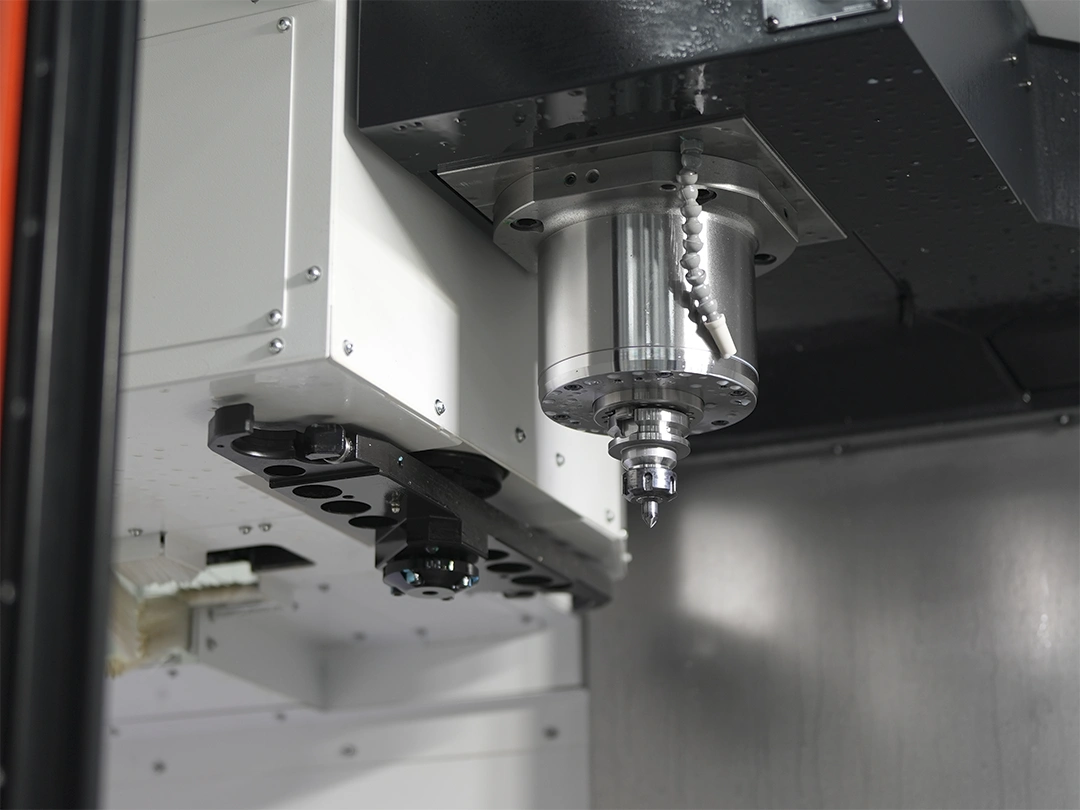

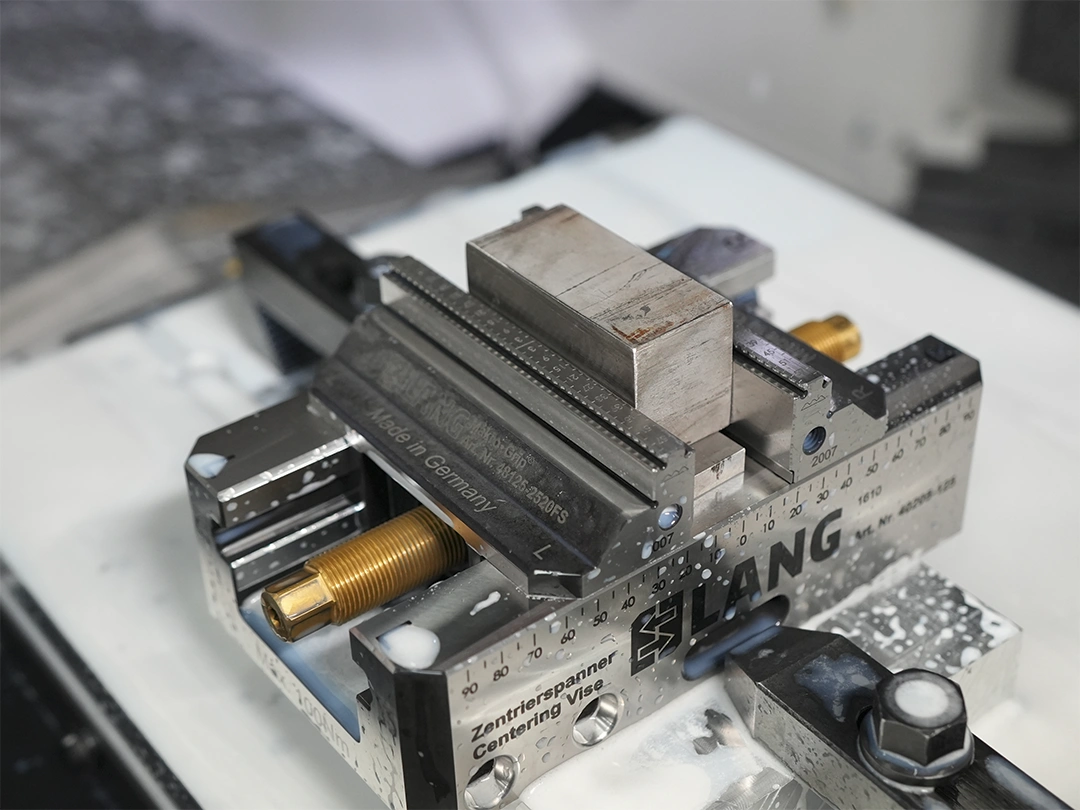

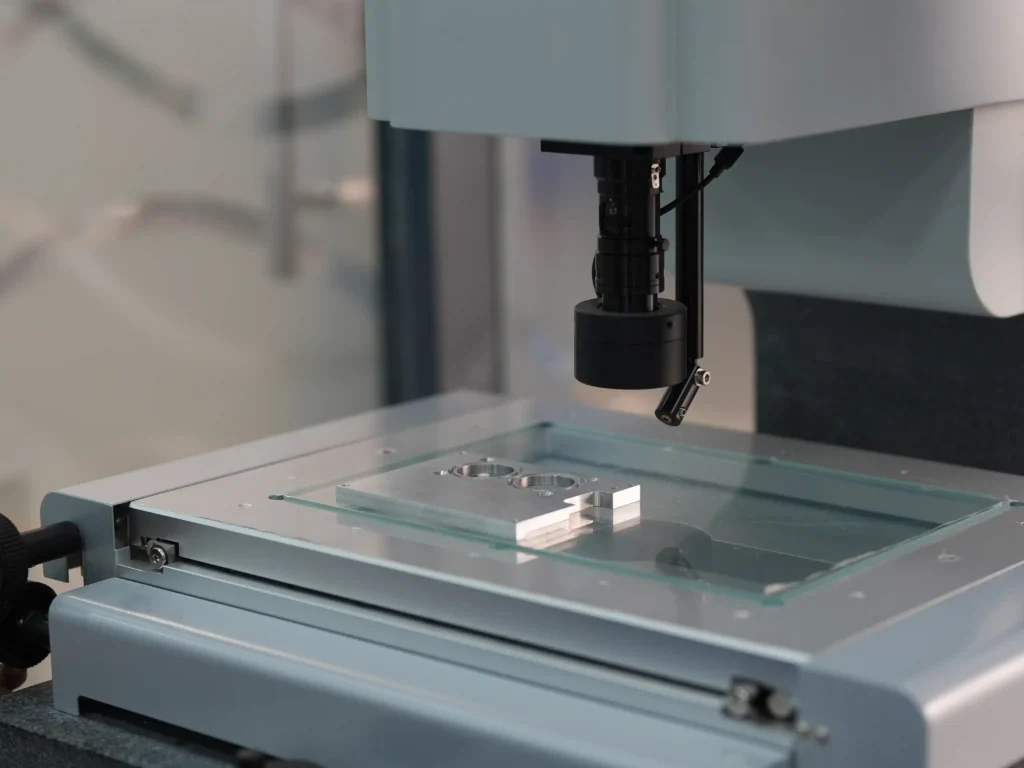

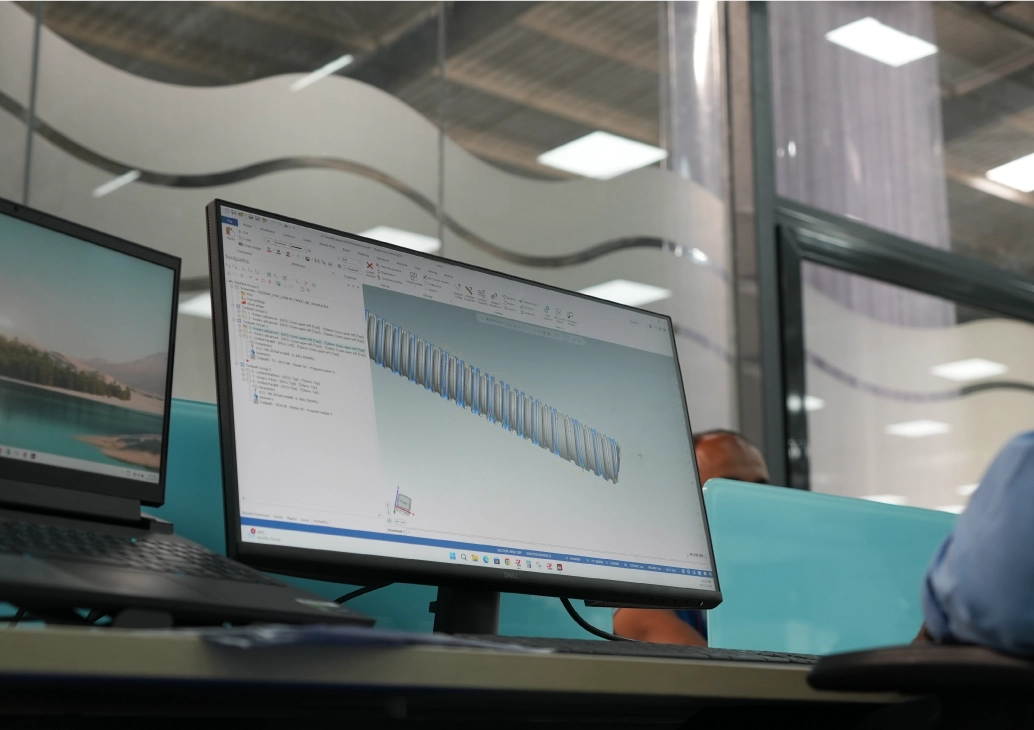

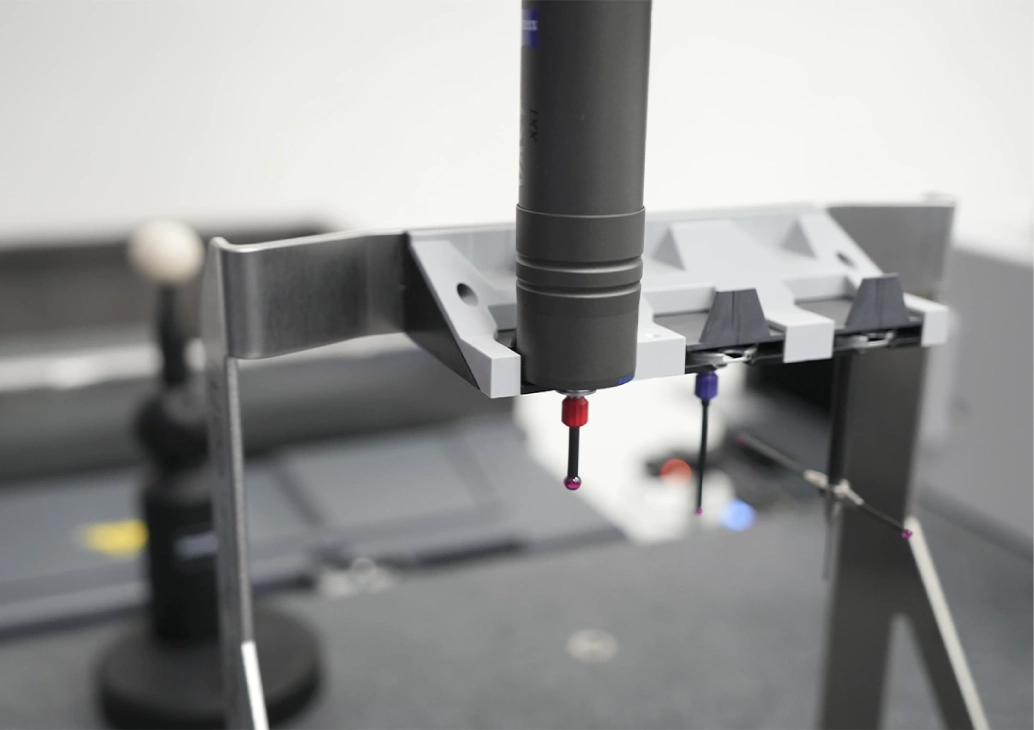

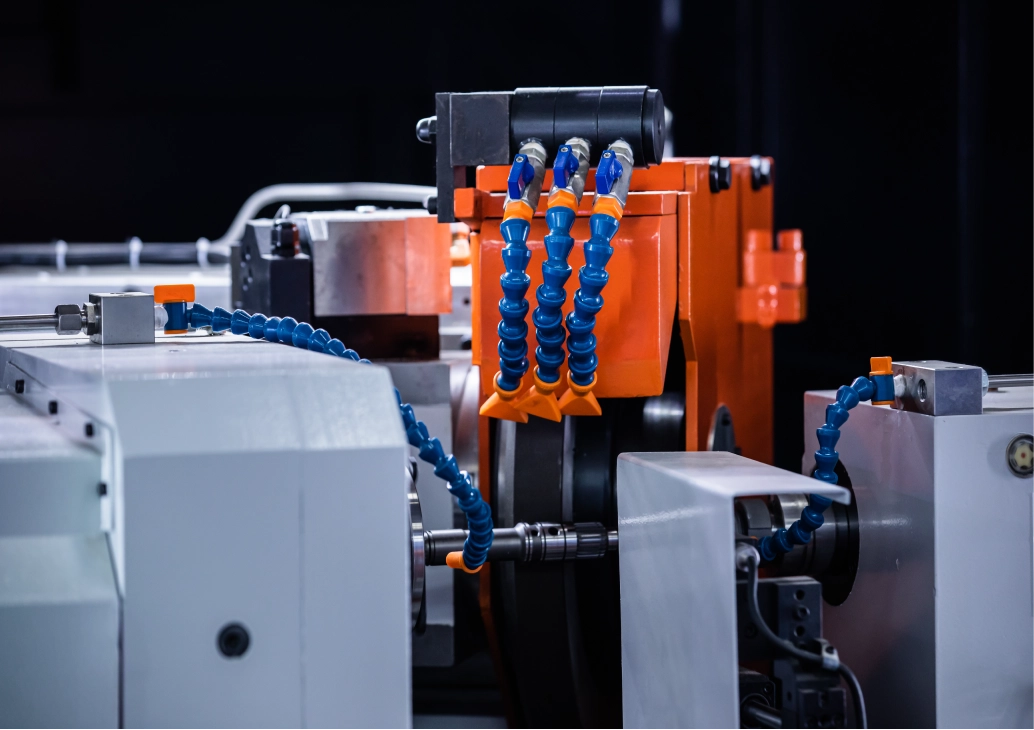

Waveultra’s infrastructure supports high-precision automation and aerospace manufacturing, with advanced CNC machining, digital workflows, and quality systems ensuring accuracy and traceability.

Integrated Manufacturing Infrastructure

01.

50,000+ sq. ft. manufacturing space

02.

Advanced multi-axis CNC machining

03.

Digital workflows with full traceability

04.

120+ in-house engineering professionals

Fastrack Your Career

Discuss Your Requirement

Reach out to explore feasibility, process approach, and precision standards.